More efficient production thanks to RTLS technologies on the store floor

17. February 2025

Positioning made easy: The best methods for precise location determination

Positioning is much more than a technical buzzword - it is the key to increasing efficiency and control, both in the private sphere and in modern industry on the way to the smart factory. In everyday life, we use positioning to navigate easily from A to B. In production and logistics, positioning technologies ensure transparency and smooth processes, making them indispensable tools that help us to act faster and more precisely.

Imagine knowing where your materials, tools or production aids are at all times. No chaos, no delays, just maximum planning and precision. But which location technology is best suited to your needs? Let us first clarify the basics and then find out how you can secure real competitive advantages with the right location solution.

What is localization?

Location means knowing exactly where something is at any given time. But it is about more than just a point on a map. It is about making movements, positions and processes visible in relation to their surroundings in order to make decisions even faster and more informed or to automate processes.

The reality is that a lost tool or a misplaced pallet can bring entire production lines to a standstill. Such bottlenecks can be avoided if the material flow is recorded in real time and tracked seamlessly. Positioning puts an end to the guesswork and provides you with the data you really need within a production site or along the supply chain - reliably, accurately and immediately available.

Whether spot identification or precise real-time tracking: Depending on requirements, there are a variety of location technologies and tracking systems that help companies to make processes more transparent, reduce search times and control material flows in a targeted manner. This enables companies to make their production processes more efficient, increase throughput and sustainably improve product quality.

The building blocks of successful tracking solutions: What you need to know:

Positioning technologies are the linchpin of efficient processes on the store floor. They help companies to improve their production and logistics by determining the position of objects or materials in real time. These tracking systems use different procedures and mathematical methods to calculate object positions.

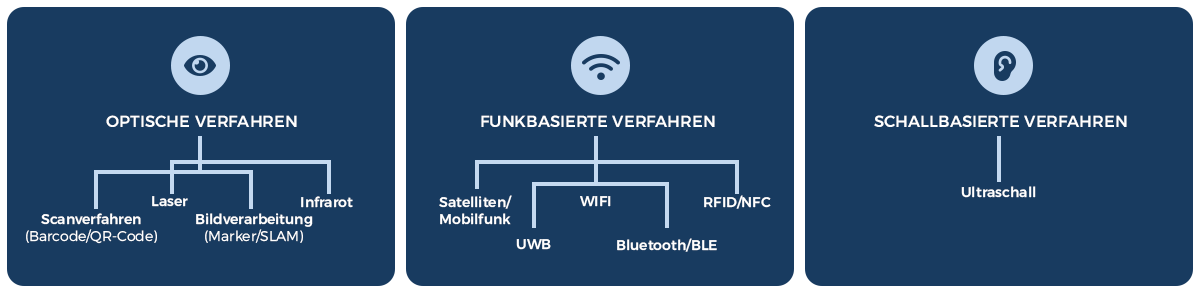

Whether indoor or outdoor tracking - there are numerous technologies that vary depending on the application.

But which technology suits your requirements? The most common methods and tracking technologies can be divided into the following categories.

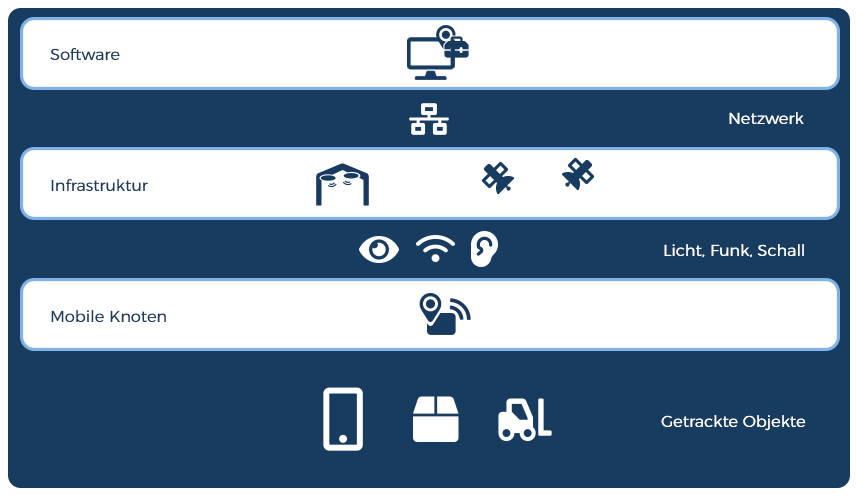

From tracker to receiver: this is how tracking becomes possible

For tracking technologies to be fully effective, all components must work together. Trackers, transponders or tags are attached to objects that need to be tracked - such as pallets, tools or transport vehicles. The necessary infrastructure is provided by satellites, mobile phone masts, sensors, receivers and readers. Together with software solutions for Industry 4.0, these components form the foundation on which modern tracking solutions are based.

The accuracy and frequency of the position calculation depend on the specific characteristics of the various positioning technologies. Positioning can take place selectively, similar to a snapshot, or continuously, as with a video that records movements without gaps.

If the position calculation is precise, closely timed and almost instantaneous, this is referred to as a real-time location system (RTLS).

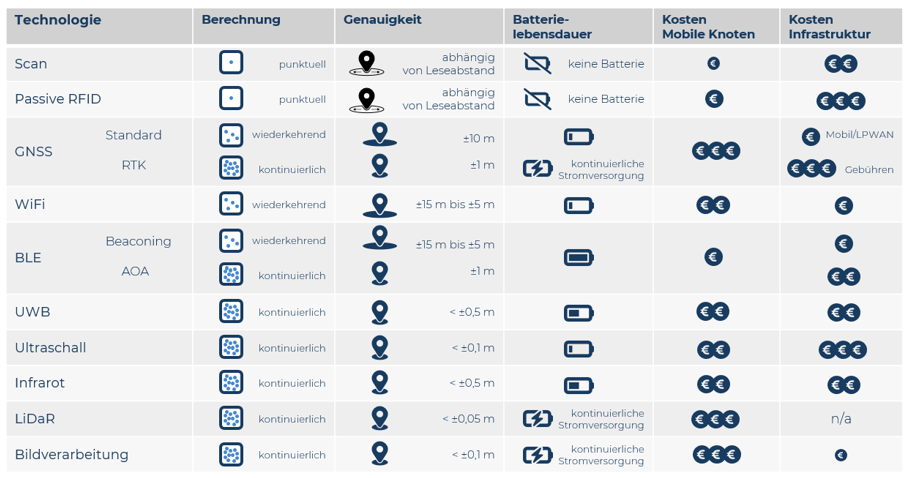

Here is an overview of the most important technologies and their main features:

Selective identification

These tracking systems record positions indirectly through the interaction between an object and a reader, a kind of "snapshot" of the status at a certain point in time.

Scanning process via barcode/ QR codes:

Scanners or digital cameras enable the rapid identification of product information via 2D barcodes or QR and data matrix codes on a label with direct line of sight. The data is captured manually as part of a process or automatically when a label enters the defined capture area, for example on a conveyor belt. A checkout scanner in a supermarket uses the same principle to read the barcode of a product and retrieve the price.

Passive RFID (Radio Frequency Identification)/NFC (Near Field Communication)

RFID/NFC supports the automated or manual identification of objects without visual contact. A battery-free RFID transponder is activated by a reader to transmit data when it is in the close range of the reader. Liquids or metal can interfere with the reading process. A well-known example is access cards that are read before passing through a turnstile.

Automatic, continuous recording of presence and positions

Here, the presence or positions of objects are recorded at regular intervals - similar to a flip book, which depicts movements in discrete individual images.

GNSS (Global Navigation Satellite System)/GPS (Global Positioning System)

GNSS/GPS provides a rough location of around ± 10 m outdoors. It uses satellites to determine the position, whereby visual contact with the satellites is required - a technology that is used, for example, in anti-theft devices for high-quality bicycles.

Mobile radio

By logging on to mobile phone masts, the position is determined with an accuracy of several hundred meters. An active connection to the network and sufficient coverage are required. When making emergency calls with a cell phone, the approximate location can be determined via the connection to the nearest cell tower.

Wi-Fi/WLAN

By measuring the signal strength or propagation times between devices and access points, WLAN can roughly determine positions - from several tens of meters to just a few meters. An additional WLAN infrastructure is often necessary and metallic bodies interfere enormously with the accuracy of location determination. Smartphones use this technology for navigation apps in public buildings or airports, for example.

Bluetooth Low Energy (BLE) Radio Beaconing

Permanently installed, battery-powered beacons continuously transmit signals that are used by mobile receivers to automatically detect presence in a room or a limited area. A simple and cost-effective solution for location-based applications - also found in shopping centers, where beacons provide smartphones with location-based offers.

Precise, continuous positioning with high accuracy in real time

Technologies such as RTLS make it possible to track movements in high resolution, just like in a video recording. Methods such as trilateration (distance to at least three points) and triangulation (angle measurement) enable precise positioning with sub-meter accuracy.

Bluetooth Low Energy (BLE) Radio Angle of Arrival (AoA)

Mobile tags use energy-saving BLE to communicate with receivers. The location is determined by calculating angles of arrival (AoA) and triangulation with an accuracy of around 1 m - a technique that is used in factories, for example, to track BLE tags on tools.

Ultra-wideband (UWB) radio

These systems use radio waves, which enable robust time-of-flight measurements between mobile tags and anchors by means of signal spreading. Metallic interference is minimized and the positioning systems achieve an accuracy of less than 0.5 m - for example with Apple AirTags, which precisely indicate distances and directions.

Ultrasound

Ultrasonic systems measure the travel time of sound waves outside the human hearing range in order to determine positions very accurately. The distance is measured by transit times and converted into centimeter-precise position data using trilateration - according to the same principle that bats use to locate their prey.

Infrarot (IR)

IR systems use infrared rays and measure the transit time of the signals to determine the location of an object. Direct visual contact between the transmitter and receiver is required, as obstacles can block these signals. This technology is used in hospitals, for example, to locate patients.

Light Detection And Ranging (LiDAR)

These systems use laser pulses to localize objects themselves and create a map of their surroundings (SLAM). The position is determined with centimeter accuracy by measuring the time of flight of light pulses, whereby unobstructed visual contact is required. Autonomous vehicles use this method to detect obstacles and navigate safely.

Image processing (marker)

Camera systems capture visual markers, such as QR codes or special patterns, which are attached to objects or fixed structures. The position of the object is determined based on the geometry and alignment of these markers. Clear visibility, good lighting and powerful cameras are required for this process. This principle is used in warehouses, for example, where forklift cameras detect markers on columns in order to precisely determine their own position.

RTK GPS (Real-Time Kinematics)

RTK GPS enables very precise location tracking in real time in the sub-meter range. National surveying services provide correction data for a fee. This requires a GPS receiver with a continuous power supply. This technology is used in agriculture, for example, to support machines in autonomous tracking during planting or harvesting.

Productivity without obstacles - how localization helps SMEs move forward

As you have already noticed, location technologies are a real game changer - also for SMEs. With location technologies, SMEs can increase their efficiency and manage the store floor more precisely, with the most important benefits including

Real-time monitoring

Early identification of bottlenecks

Increased efficiency

Cost reduction

Data-based decisions

Simple integration

User-friendly dashboards

Which positioning technology will get your processes on track and remove your hurdles?

With so many options available, choosing the right tracking technology can be like looking for a needle in a haystack. Cost, accuracy, frequency and response time of position updates, battery life and integration - all these factors have to fit together perfectly. Because each technology has its advantages and disadvantages.

From barcode scanning for quick identification to high-precision UWB or LiDAR systems for centimetre-precise location - each solution has its strengths. The right choice makes all the difference: it creates transparency, reduces search times, optimizes transport routes and thus increases overall productivity.

The key advantages and disadvantages at a glance:

At INDUTRAX, we know the advantages and disadvantages of all tracking technologies and can provide you with manufacturer-independent advice. Together, we will find the tracking solution that perfectly matches your requirements - without compromise, so that your processes finally run just as efficiently and transparently as you have always wanted.

Visit us in our demo factory and discover various RTLS systems and locating technologies in practice, to "touch" and try out before you make a decision.

Make an appointment directly

Let our experts advise you individually and independently of the manufacturer!

With our Expertise in the design and implementation of Industry 4.0 solutions with tracking technologies and RTLS we present you with proven strategies that Iyour production and logistics processes transformure.

Error: Contact form not found.