Positioning made easy: The best methods for precise location determination

3. March 2025

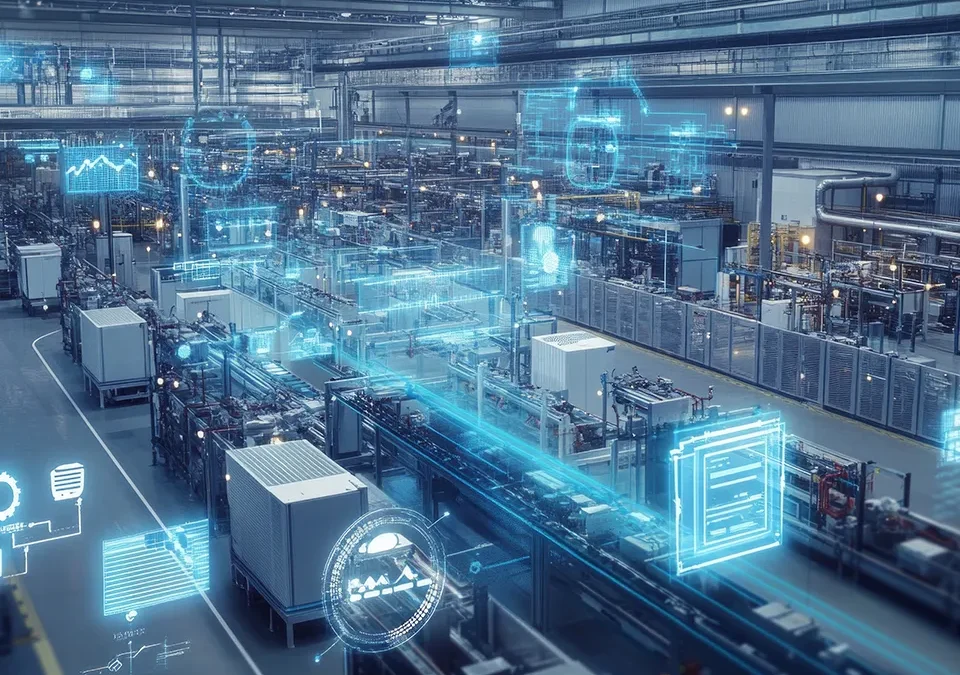

More efficient production thanks to RTLS technologies on the store floor

How tracking technologies optimize your processes

Imagine your company produces a large number of different products every day. As your customers' demand increases, so does the complexity of your production processes. You have to produce more and more variants, but long search times for materials, semi-finished products and tools are constantly slowing down your efficiency. Your employees spend valuable time searching for the right objects - time that you are missing elsewhere. The result: delays, unnecessary costs, possible machine downtime and dissatisfied customers.

The consequences are enormous: every moment that employees spend searching for objects or tools means lost working time and increased production costs. And the consequences go further when the entire workflow is delayed, bottlenecks occur, employees come under pressure, frustration increases and productivity decreases.

RTLS - The key technology for optimized production and logistics

From our experience we can say: you are not alone! We see the same challenges in many companies. When search times and a lack of transparency become a bottleneck, this quickly becomes a competitive disadvantage. It's time to change the situation.

With modern RTLS and tracking technologies, you create the basis for a completely new level of transparency and efficiency in your production and logistics. Automatic positioning, immediate feedback in the event of faulty transports, reliable localization of your objects and the recording of movement histories provide valuable insights to continuously improve your processes.

Our focus is on the provision of software modules for the simple integration of a wide range of positioning technologies into your corporate landscape.

Improved production and logistics processes with RTLS solutions from INDUTRAX

- Optimize working time: Say goodbye to hours of searching for materials, tools and orders. With precise real-time location, your employees will gain back valuable working time and increase productivity.

- Transparency and overview: Our technology-independent tracking technology enables you to consistently localize and track goods and materials using real-time tracking or RFID, both internally and externally. This allows you to keep track of the status and location of production equipment at all times.

- Efficient process design: Our solutions help you to improve information flows, avoid media disruptions and accelerate decision-making. Seamless integration into existing systems such as ERP, MES and WMS allows you to optimize your entire production and logistics processes.

- Increase throughput: Thanks to data-driven analyses from the recorded movement histories, you can make targeted process improvements that lead to an increase in throughput, avoidance of bottlenecks and optimized use of resources.

- Flexibility and investment security: Rely on scalable solutions that adapt to your changing requirements. Our software is compatible with various tracking technologies - from RFID and GPS to ultra-wideband - and ensures future-proof tracking and investment.

- Practice-oriented support: INDUTRAX accompanies you from the initial idea to full implementation. Start with a pilot project and expand the localization technology step by step to maximize the benefits in your production.

Rely on INDUTRAX to make your production and logistics processes more efficient, minimize search times and bottlenecks and increase your competitiveness - with a user-friendly, flexible and scalable software solution.

Practical example: RTLS in use at an automotive supplier

In order to increase efficiency in production and reduce manual errors, a leading automotive supplier relies on a combination of real-time location technologies and intelligent software. Our case study shows how the use of RTLS has led to a significant reduction in search times, optimized process control and greater transparency in production:

Initial situation: The challenges without RTLS

Constantly on the hunt for objects, tools or orders? Unclear processes and long search times hinder the entire production process. Manual documentation also leads to errors and makes everything even slower.

The production of fasteners for an automotive and construction industry manufacturer is carried out on an order-related basis in varying process sequences, sometimes across several production plants and with the involvement of subcontractors. Several thousand orders can be in process at the same time. This situation leads to a number of challenges, particularly in terms of creating transparency and avoiding manual and paper-based efforts. The biggest challenge in managing production was the long search times for orders and dealing with errors in manual documentation during order processing.

Measurable benefits for the store floor with RTLS

The clever solution, which combines order data from SAP with real-time position data from location technologies in intuitive interfaces for the store floor, not only enabled a significant reduction in search times of up to 75%, but also provides the basis for automatic documentation with the help of precise tracking of order movements.

The use of pick-to-light in combination with real-time location technology ensures that orders can be quickly identified even in stacked load carriers. The automatic recording of position changes is used to make automatic bookings such as blocking bookings. This not only reduces errors from manual documentation, but also increases the efficiency of the entire logistics process. In addition, the recorded historical movement data can be used to provide impetus for optimizing production throughput and resource utilization.

The right RTLS solution

More efficient production thanks to RTLS technologies on the store floor: Thanks to the use of RTLS and GPS technologies, the exact position of orders and materials can be tracked in real time within the production areas as well as as in the flow to the plants. A combination of Quuppa BLE RTLS and GPS trackers was used to localize the load carriers for the transport of production orders. The use of INDUTRAX software with the PRODUCTTRACKER application enabled seamless, bi-directional integration with SAP S/4 HANA, utilization of position data from RTLS and GPS, derivation of automatic bookings and notifications, as well as effective visualization of production processes, which enabled precise control and faster decision-making.

Get your individual RTLS consultation!

Error: Contact form not found.